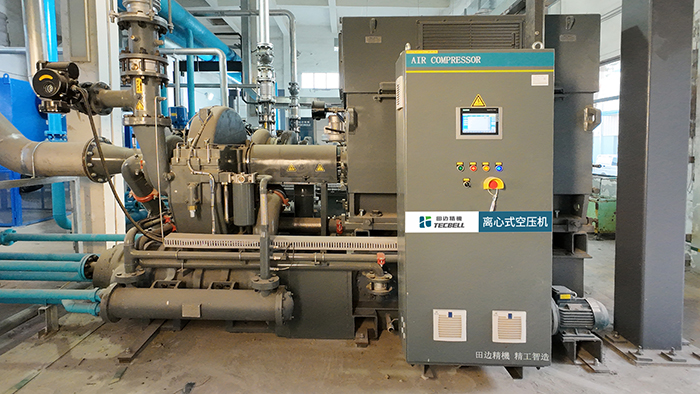

TECBELL remains committed to driving high-quality development in the manufacturing industry through technological innovation. Looking ahead, TECBELL will continue to deepen its expertise in intelligent compressed air systems, continuously optimizing product performance and energy efficiency.By providing power battery manufacturers with safe, reliable, green, and sustainable compressed air solutions, TECBELL helps customers gain a competitive edge in an increasingly demanding market and jointly advance the industry toward a more efficient, low-carbon, and sustainable future.