In an era of rapid technological advancement, vacuum technology has become a key driver for improving quality and efficiency across industries — from precision manufacturing of new energy vehicles and cutting-edge semiconductor processes to food processing and preservation. TECBELL is helping clients overcome diverse industrial challenges through core technology innovation. Let’s explore the breakthroughs and real-world applications of TECBELL’s screw vacuum pumps.

Empowering Industries: Multifaceted Applications of Screw Vacuum Pumps

▼ New Energy Vehicle Industry: Electronic Component Packaging

Project Background:During the packaging of electronic components in new energy vehicles, precision parts must be processed in a clean vacuum environment to prevent contamination and ensure process integrity and product reliability.

Solution:

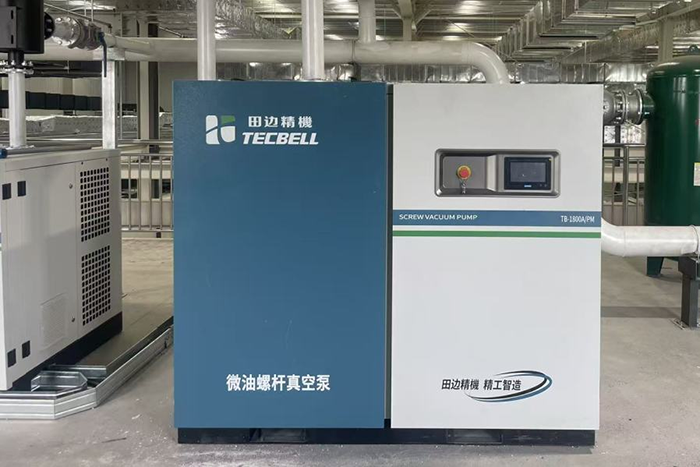

TECBELL’s screw vacuum pump delivers excellent vacuum performance and cleanliness, providing a stable and reliable vacuum environment that meets the industry's stringent requirements for high precision and cleanliness.

Results:

Ensured packaging quality of electronic components, increased product yield and production efficiency, and helped new energy vehicle manufacturers enhance their core competitiveness.

▼ Semiconductor Industry: Vacuum Pick-and-Place & Encapsulation

Project Background:

Chip production processes such as pick-and-place and plastic encapsulation demand ultra-clean and highly stable vacuum conditions. Even minor contamination or vacuum fluctuations can affect chip performance and yield.

Solution:

TECBELL customized a centralized vacuum system featuring three 37kW and one 75kW screw vacuum pumps. The new system enables smart centralized control, offering convenient and efficient operation and maintenance.

Results:

Total installed capacity was reduced by approx. 110kW, achieving a comprehensive energy-saving rate of 35% and cutting annual electricity costs by RMB 704,000. The pump’s stability and cleanliness perfectly meet the stringent requirements of the semiconductor industry, significantly improving both production efficiency and product quality.

▼ Food Processing Industry: High-Speed Vacuum Sealing

Project Background:

A meat processing company faced issues with numerous rotary vane pumps cluttering the production site and causing frequent breakdowns, which delayed operations.

Solution:

TECBELL introduced oil-injected screw vacuum pumps known for high-efficiency pumping and stable performance, successfully resolving the company’s production bottlenecks.

Results:

Achieved a comprehensive energy-saving rate of approx. 32%. Equipment ran stably with virtually no delays due to breakdowns, significantly reducing long-term operational costs and enhancing both production safety and economic benefits.

Core Technology Highlights

Permanent Magnet Variable-Frequency Motor Technology

Motor efficiency exceeds 97.8%, surpassing first-class energy standards. Speed adjusts on demand via variable frequency, boosting energy conversion efficiency. Overall energy savings: approx. 30–50%.

Intelligent Variable-Frequency Control System

Integrated with advanced algorithms and sensor technology, the smart controller accurately detects system status and adjusts accordingly to reduce idle operation. This enables intelligent, fine-tuned management and unlocks deeper energy-saving potential.

High-Reliability Host Design

The vacuum pump rotor is self-lubricated under negative pressure, ensuring low energy consumption and minimal failure rate. The oversized main rotor and SKF heavy-duty bearings provide stable performance, lower noise, and top-tier reliability and service life.

Advanced Oil Cooling System

Effectively maintains optimal operating temperature during high-intensity operation, prolongs lifespan, and ensures consistent performance and energy efficiency.

Facing the dynamic demands of the market and evolving technologies, TECBELL will continue investing in R&D to optimize the performance and energy efficiency of screw vacuum pumps. In the future, TECBELL will focus on smart and green development, exploring new technologies and processes to deliver more efficient, energy-saving, and environmentally friendly vacuum solutions for global clients.